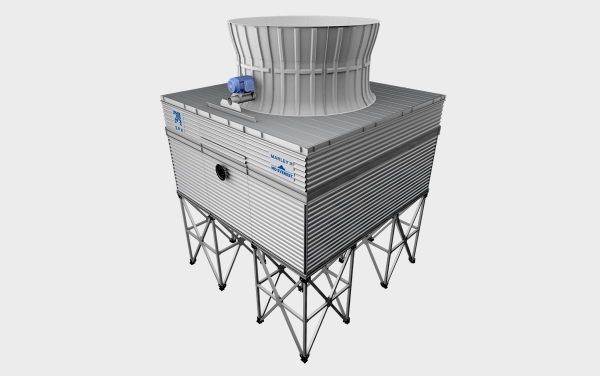

Marley® NC®

Crossflow Cooling Tower

Since it launched in 1968 for all applications, the Marley NC Cooling Tower has consistently demonstrated greater cooling capacity and energy efficiency, with independently verified sound data. Offering the highest tonnage per cell and the lowest measurable drift rates to keep your surroundings clean within the city that doesn’t sleep, you can rely on the Marley NC to match your cooling requirements.

Marley® NCWD

Plume Abated Cooling Tower

Visible plume is a major concern in the high-density building environment that is New York City. Plume that obscures the view is not only aesthetically undesirable, but it can also create safety concerns. The Marley NCWD Cooling Tower is designed to reduce visible plume formation. Patented plume abatement technology offers the added benefit of water conservation. Compared to a traditional cooling tower, it offers up to 20% water savings.

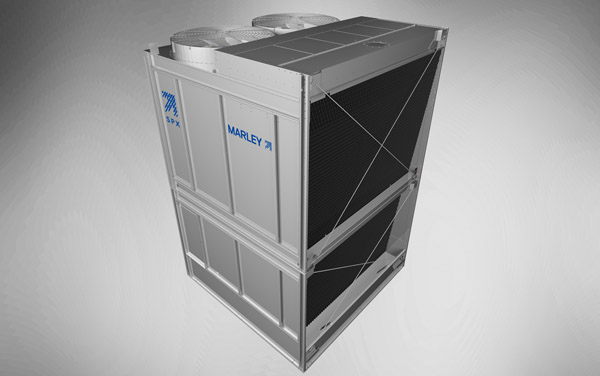

Marley® MD

Counterflow Cooling Tower

When space is limited or restricted, the Marley MD Cooling Tower simplifies installation and maintenance for HVAC and industrial customers. Its compact design, lighter weight and single inlet connection make it a versatile option. The counterflow design also provides easy access to the collection basin from all sides.

Marley® AV

Crossflow Cooling Tower

The factory-assembled Marley AV Cooling Tower is designed to minimize costs and maximize cooling tower performance through quick, easy installation and low maintenance operation. Its single flow, induced draft crossflow design offers energy savings in a small footprint installation, making it an excellent crossflow cooling tower replacement for some forced draft counterflow cooling tower installations.

Marley® Parts

OEM Cooling Tower Components

SPX Cooling Technologies, Inc., offers industry-leading Marley cooling towers and aftermarket parts that provide outstanding performance and reliability. We have the parts availability, performance, quality and service providers to maintain most cooling tower designs and brands. Learn more about Marley components here.

Non-Marley® Tower Parts

Marley Components for BAC and Evapco Towers

SPX Cooling Technologies, Inc., provides aftermarket parts for other cooling tower brands, including BAC and Evapco. Get back to your priorities and minimize maintenance requirements with high-quality Marley replacement components for non-Marley towers.

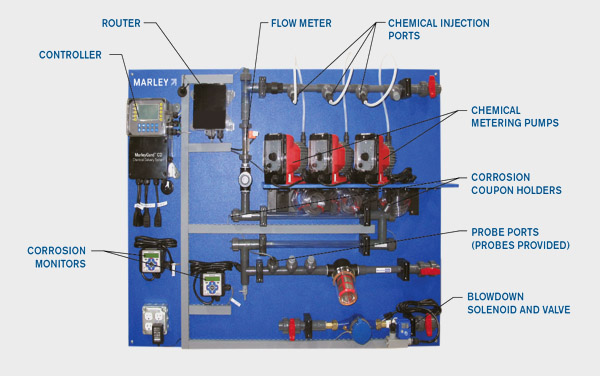

MarleyGard™

Water Management Products

Maintaining water chemistry is an essential part of an effective water management plan. The MarleyGard CD Chemical Delivery system is a robust control panel that facilitates delivery of cooling tower treatment agents. The MarleyGard SP Sweeper Piping System removes sediment and debris from cooling tower cold water basins to help prevent algae and bacteria growth.

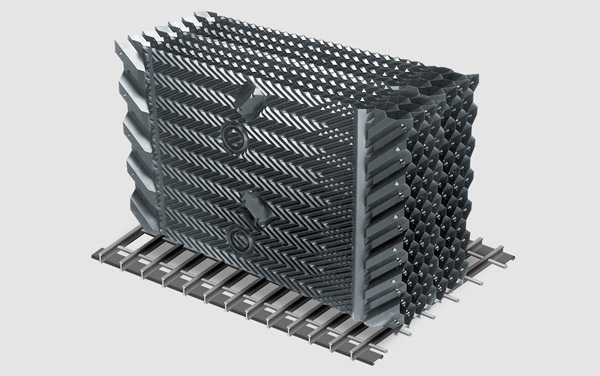

Marley® Aquatower

Crossflow Cooling Tower

Constant enhancements have made the Marley Aquatower the product of choice in over 50,000 installations since 1947. PVC film enables the Aquatower to reject more heat per unit size, and integral air inlet louvers and drift eliminators save fan horsepower by maximizing airflow through the cooling tower. Maintenance is easier with no hidden spray systems, tiny nozzles or enclosed basins; all primary components are open to view.

Marley® NC Everest®

Modular Cooling Tower

The Marley NC Everest Cooling Tower offers performance and features that tower above the rest. It is well-suited for both HVAC and industrial applications, reducing energy and installation costs for HVAC applications and field-erection costs for industrial applications. With up to 50% greater cooling capacity, energy and installation savings, and fewer components and easier maintenance, you’ll take cooling to great heights with the NC Everest.

Marley® MD Everest®

Counterflow Cooling Tower

Suitable for HVAC and process cooling applications, the Marley MD Everest Cooling Tower takes cooling to a new altitude. Compared with other preassembled counterflow towers, it offers greater than 85% more cooling capacity per cell. It also delivers to the job site 60% faster and installs 80% quicker than field-erected options.

Marley® MH

Evaporative Fluid Cooler

The Marley MH Fluid Cooler remains one of the most efficient systems and best choices for HVAC and industrial closed-loop applications. By keeping the process fluid in a clean, closed loop, and combining the function of a cooling tower and heat exchanger into one system, the MH Fluid Cooler provides superior operational and maintenance benefits. Its hybrid design combines heat transfer fill media and heat exchange coils to significantly improve performance over conventional closed-circuit coolers.

Puroflux

Permanent Media Filters

Available in flow rates of 15, 35, 65, 100, 140, 190 and 250 GPM.

Positive filtration down to 10-micron. (lower micron media available).

Non-code 304-stainless steel vessel rated at 75 psi with epoxy coated carbon steel hand-hole covers (optional higher pressure ratings, ASME code stamp, and fiberglass vessel available).

Marley® LW

Evaporative Fluid Cooler

Available in multiple footprints, the Marley LW Fluid Cooler is an induced-draft counterflow fluid cooler utilizing patent-pending heat transfer technology. Its closed-circuit design keeps the process fluid in a clean, closed loop. The LW Fluid Cooler’s lower height and quiet operation also addresses many municipal restrictions. Installation and maintenance advantages include one-piece assembly, requiring a single lift and fully integrated factory controls.

Recold® JW

Evaporative Fluid Cooler

The Recold JW is a quiet, forced draft fluid cooler with a lighter weight, corrosion resistant copper coil. Its low profile design simplifies integration into existing building mechanical systems and can be placed indoors or out. Quality materials and construction provide many years of reliable operation with minimal maintenance requirements.